Paul Yale and Brooke Sizer, lawyers at Gray Reed & McGraw in Houston, published an article in the most recent Section Report of the Oil, Gas & Energy Resources Law Section of the State Bar, “ A Brief Look at the Law of Hydraulic Fracturing in Texas and Beyond.” It will be published in a future issue of The South Texas Law Review. It is an excellent overview of the development of horizontal drilling and hydraulic fracturing and the law and controversies surrounding their use. The article is balanced and fully supported by citations to resources and authorities.

The authors cover the benefits and risks of hydraulic fracturing, including reduction of foreign imports, jobs, reduced prices for consumers, water quality and usage, air quality, earthquakes, and social impacts. It gives a balanced view of the ongoing debate over whether increased use of natural gas for generation of electricity reduces greenhouse gas emissions, whether there is a connection between hydraulic fracturing and earthquakes, and adverse impacts on roads and other infrastructure.

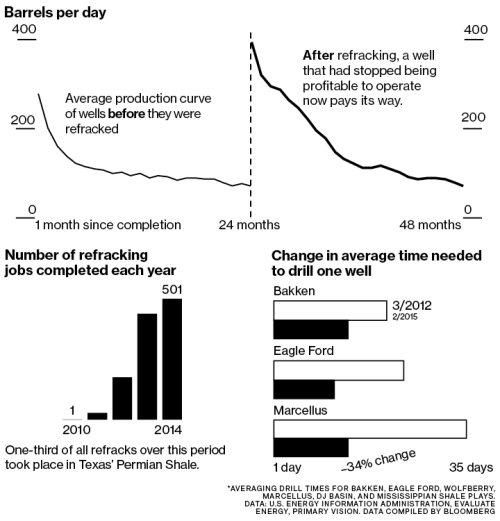

The article also contains information on the process of hydraulic fracturing itself:

Oil and Gas Lawyer Blog

Oil and Gas Lawyer Blog